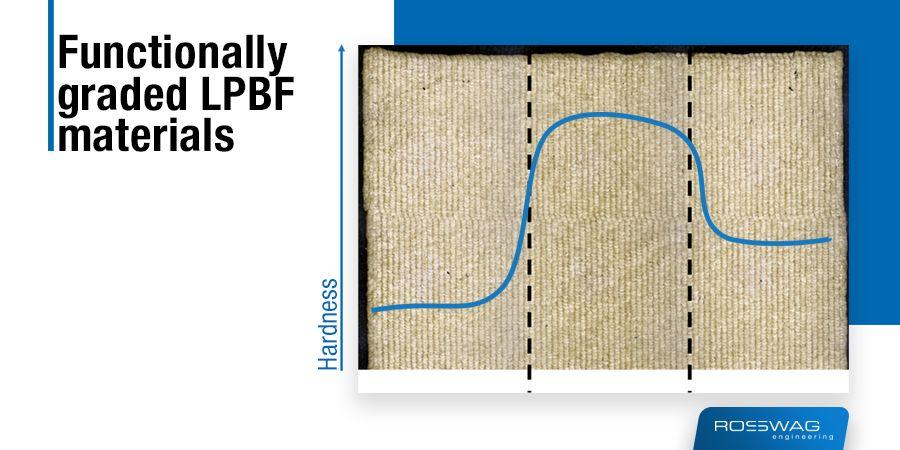

Tailored material properties

One material, one parameter set, one melt pool structure - but still tailor the material properties ⁉️ Unleash the full #MetalAM potential on #MaterialsMonday 🚀

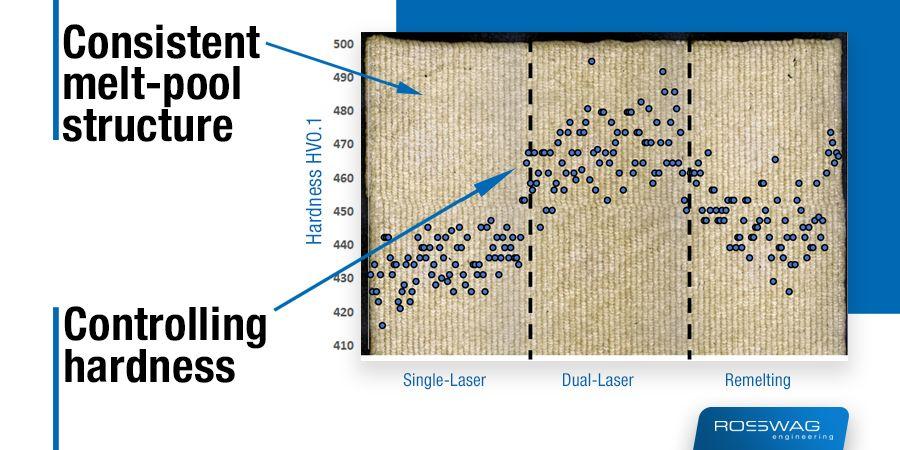

Controlling the material properties and still obtain a consistent melt pool structure is a major challenge in the LPBF process. Gregor Graf did some impressive studies to tailor the hardness of our high-performance tool steel Specialis® according to the application requirements.

🌟 Highlights 🌟

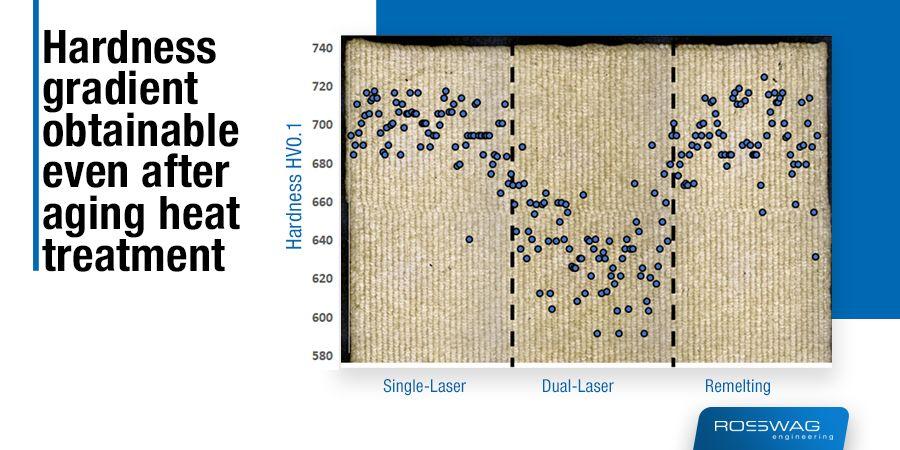

☑️ Hardness up to 65 HRC / 820 HV with Specialis® material

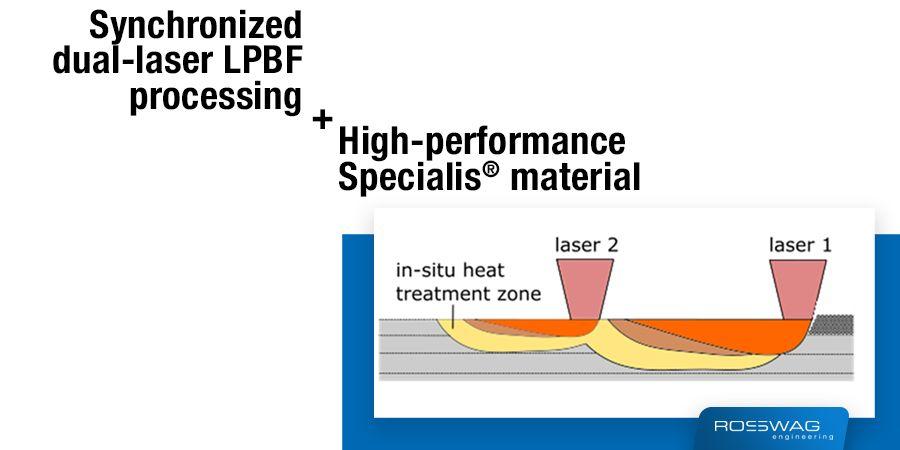

☑️ Synchronized dual-laser LPBF processing on SLM Solutions SLM 280

☑️ Tailored material properties maintainable even after heat treatment

Questions or applications regarding this material or processing strategy ❓ Get in touch 🤙

Further information:

- Research Paper “Dual-Laser PBF-LB Processing of a High-Performance Maraging Tool Steel FeNiCoMoVTiAl”: https://doi.org

- Research Paper “Characterization of a novel maraging steel for laser-based powder bed fusion: optimization of process parameters and post heat treatments”: https://doi.org

- High-performance maraging tool steel Specialis®: Material Datasheet

- Trade optimized LPBF process parameters on AddiMap marketplace: https://addimap.com

- Join the Metal AM insights newsletter: Subscribe