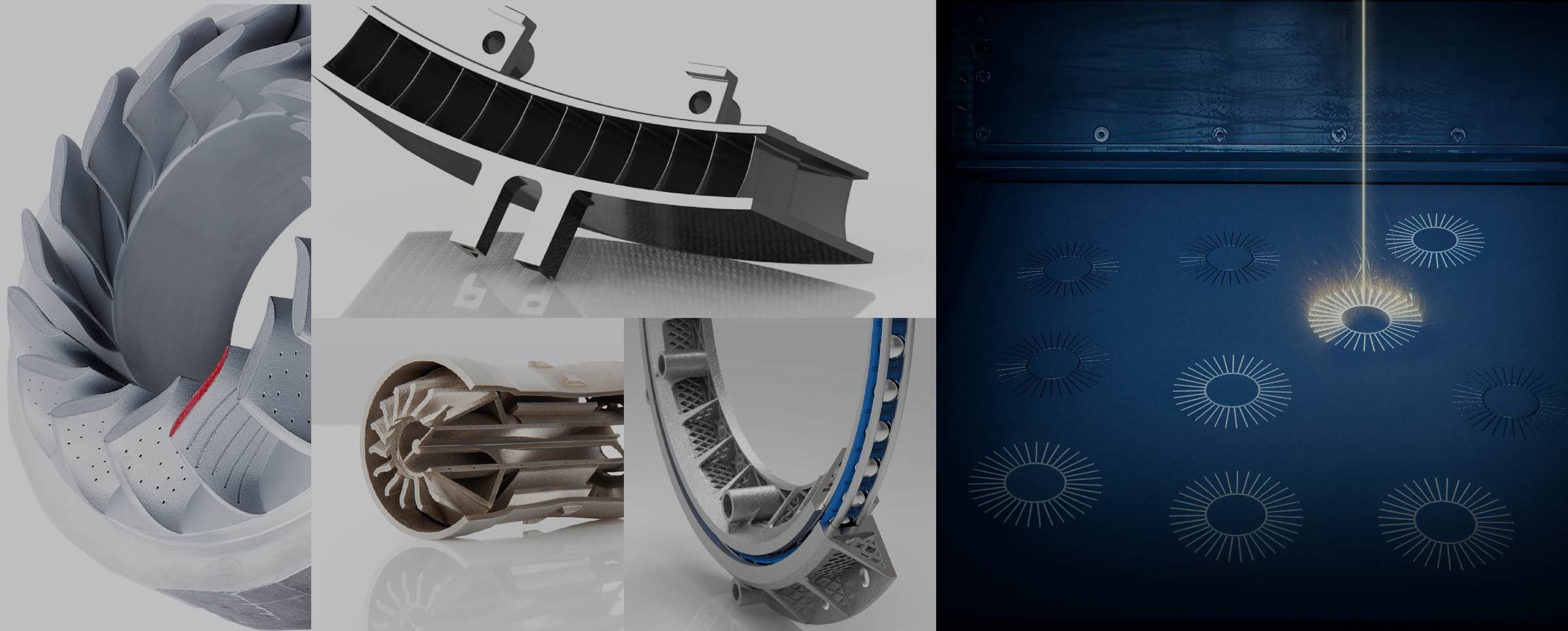

All processes from a single source

Rosswag Engineering specializes in metal 3D-printing by selective laser melting (SLM® / LPBF) in a holistic and in-house process chain. This enables the efficient and economical production of functionally optimized metal components from many different alloys. The portfolio of our services ranges from tool production and prototypes with small quantities, to series production of functional components and specific consulting for the qualification of materials and parameters in an individual process chain.

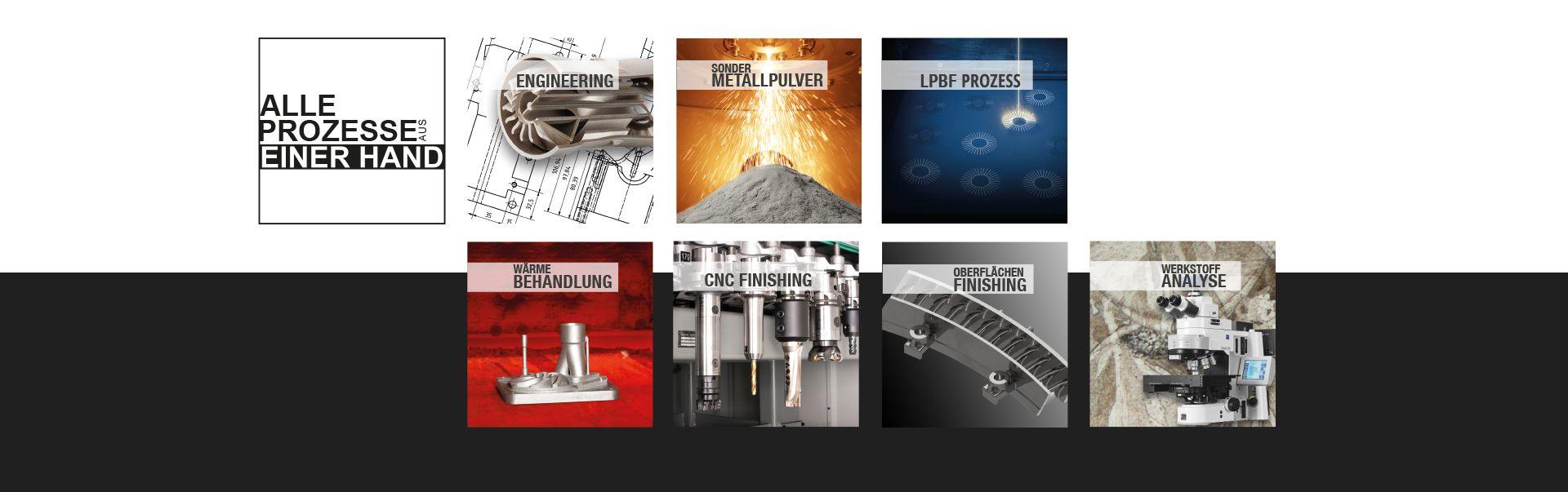

Process Chain

Rosswag Engineering offers a globally unique process chain for Metal Additive Manufacturing. The service portfolio ranges from tooling and prototype production with small quantities to series production with specific consulting services for the qualification of materials, process parameters and individual process chains for high-demanding parts.

Metal 3D-Printing Applications

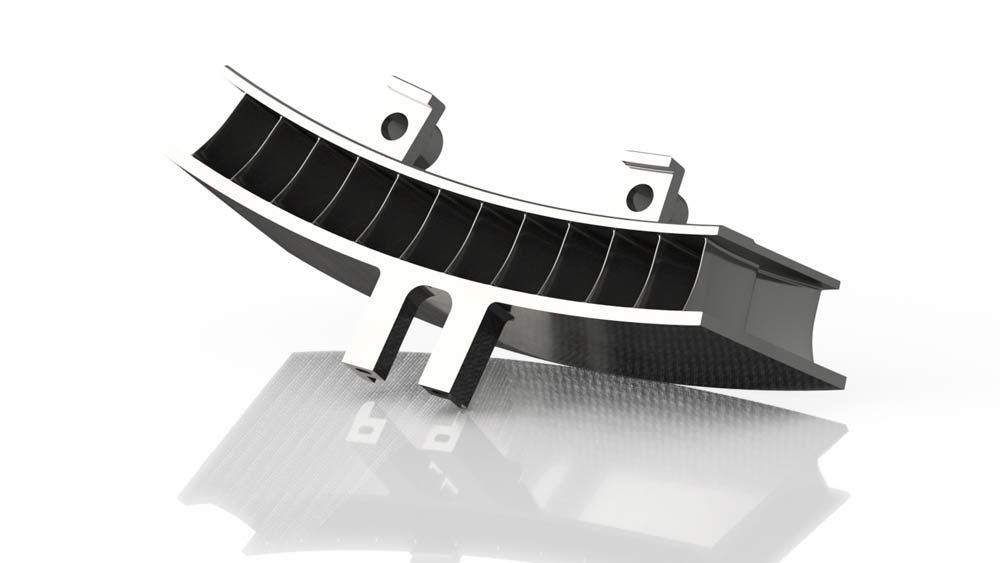

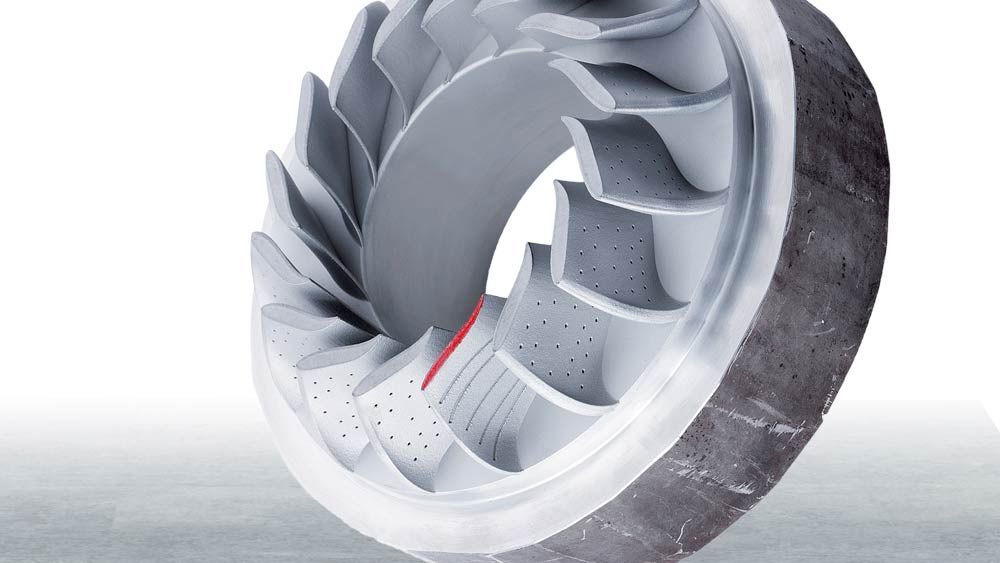

For an economically advantageous use of the metal 3D-printing process, functional added values can be integrated into the components. For example, topology-optimized lightweight structures or cooling channels close to the contour can have a major influence on the rapid amortization of production costs over the life cycle of the component. Furthermore, entire assemblies can be combined into individual components to reduce subsequent expenditures in joining and testing processes.

Rapid Prototyping

Additive manufacturing enables the fast and cost-efficient production of complex and mass-individualized components. The tool-less and mold-less manufacturing process means that no additional costs are required to produce initial prototypes in a short time. The use of metal 3D-printing can thus significantly reduce time and cost expenditures in the development phase of series products.

Series production

Metal 3D-printing is already used at Rosswag for series components in quantities of 10 to about 10,000 components per year. Functionally optimized added values, mass-individualized geometries or even special materials result in attractive business cases in each case thanks to our unique service portfolio. We ensure reproducibly high component quality even for large quantities through our TÜV SÜD-certified QM systems and in-house process chains.

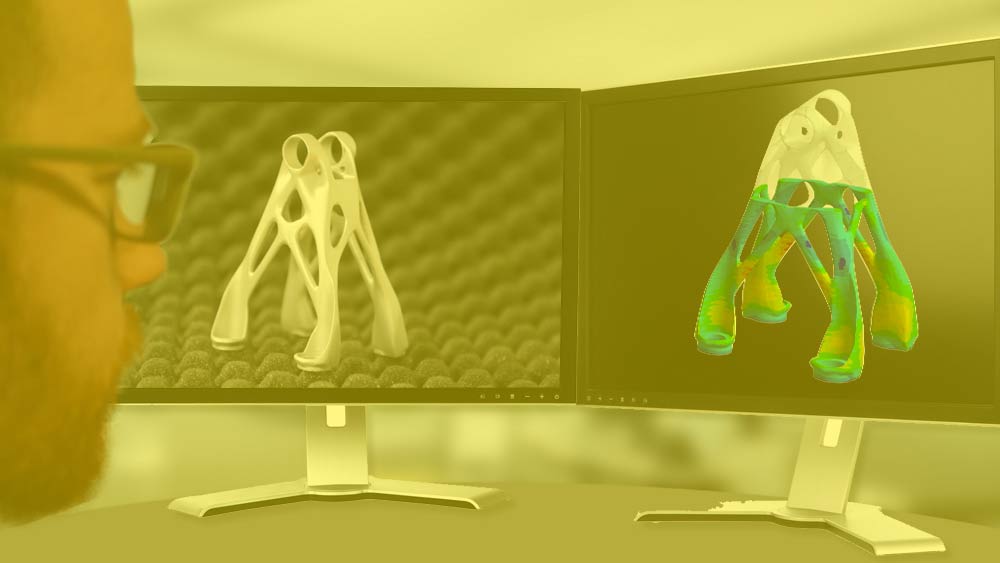

Lightweight design

Metal 3D-printing and simulation-based topology optimization can reduce component weight without compromising strength. Particularly in the case of moving masses, this results in a large savings potential over the component life cycle. In addition, the manufacturing costs of metal 3D-printing are reduced with every gram of component weight saved. Selective laser melting (LPBF) enables the production of cavities, honeycomb and lattice structures or bionic geometries and is a relevant key technology for aerospace technology in terms of lightweight design potential.

Toolmaking

Additive manufacturing is ideally suited for demanding tool and mold making. The layer-by-layer structure of metal 3D-printing enables the production of flow-optimized and near-contour cooling and heating channels, which optimally temper molds and tools and thus reduce cycle times. When used in the machining industry, the service life of cutting inserts can be significantly increased through the targeted supply of cooling lubricant.

Hybrid manufacturing

By combining conventional manufacturing methods with metal 3D-printing processes, hybrid component structures with added functional values can be produced cost-effectively. A process chain such as Rosswag's ForgeBrid® enables the cost-effective production of solid component geometries through forging processes. These high-strength basic bodies are then complemented with function-optimized structures from metal 3D-printing by means of material-fit connections.

The characteristic system parameters and technical boundary conditions of an SLM® 280 Twin are shown in excerpts below:

| Plant parameters | Value |

|---|---|

| Installation space [x/y/z] | 280 x 280 x 350 mm3 |

| Laser power | 2x 400 W |

| Layer thickness | 20-100 µm |

| Max. Construction speed | 40 cm2/h |

| Dimensional accuracy | ± 0.1 mm |

| Surface roughness | Ra 8-12 µm |

| Material density | > 99.9 % |

Materials

for metal

3D-printing

Rosswag Engineering has the world's most comprehensive materials portfolio for industrial metal 3D-printing. With over 40 qualified materials, we have the right material for many industry-relevant applications. With our own atomization plant and the correspondingly designed periphery for quality control and preparation of metal powders, we can also efficiently produce individual special alloys in quantities up to approx. 50 kg and qualify them in the metal 3D-printing process.

The world's fastest qualification

new metal 3D-printing materials

The in-house process chain at Rosswag enables holistic and rapid material qualification for additive manufacturing. From the atomization of individual alloys to metal powders, to simulation-supported parameter studies in the LPBF process, to comprehensive analysis of the test specimens, very short cycle times can be realized. You will receive initial results on your material qualification within a few days.

What metal 3D-printing processes are available?

In metal 3D-printing, there are a variety of different additive manufacturing processes for component production, each with advantages and disadvantages in terms of, for example, cost, component dimensions, material selection and component complexity.

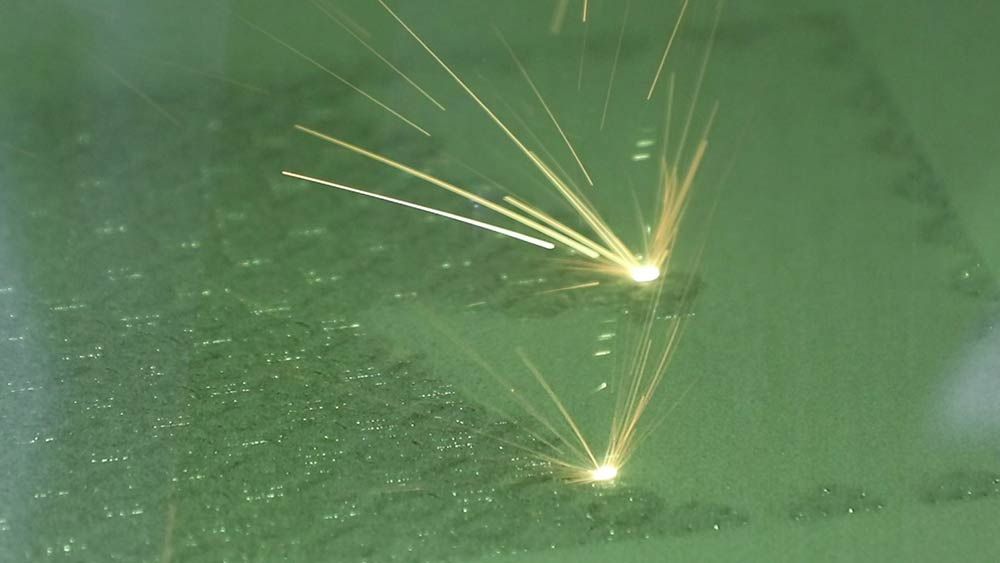

LPBF (Laser Powder Bed Fusion, PBF-LB) or SLM® (Selective Laser Melting)

- With a market share of more than 90 %, the LPBF process is most frequently used for the production of functional metal 3D-printed components. This is also Rosswag's preferred process for manufacturing metal components for industrial applications. One or more lasers serve as the energy source for local melting of the metal powder in the powder bed.

- Other frequently used process names for the LPBF process are DMLS (Direct Metal Laser Sintering), LaserCUSING, ALM (Additive Layer Manufacturing), LMF (Laser Metal Fusion), LBM (Laser Beam Melting).

The component to be manufactured is built up from metal powder layer by layer with the aid of the laser using microwelding processes. In the process, the physically dense component is created close to the final contour in the powder bed. Most of the metal powder that is not melted can be reused after the construction process.

Due to the layer-by-layer structure in metal 3D-printing, even highly complex geometries can be created without additional effort. Functionally optimized geometries include, for example, near-contour, internal channel structures through which a significantly better cooling or heating effect can be realized. There are also opportunities to combine the functions of complex assemblies in a single component. This design, known as integral construction, reduces the amount of post-processing and assembly work required because individual components are already combined with one another during production. Lightweight applications also benefit from metal 3D-printing, as topology optimization, introduced cavities or honeycomb structures at unloaded geometry areas can realize high weight savings with good stiffness.

EBM (Eletron Beam Melting, PBF-EB)

- A process comparable to LPBF with electron beams as the energy source used and usually higher process temperatures.

DED (Direct Energy Deposition)

- In the DED process, powdered or wire-shaped starting material is fed in via a nozzle and melted with a laser, electron beam or electric arc. This also enables multi-axis deposition processes on large components. Depending on the process combination used, the process is referred to as Laser Metal Deposition (LMD), Electron Beam Additive Manufacturing (EBAM), Wire Arc Additive Manufacturing (WAAM) or Wire Laser Additive Manufacturing (WLAM).

Metal Binder Jetting

- Also known from the plastics sector, metal binder jetting involves the selective bonding of metal powder in a powder bed by means of a binder. The resulting green part is then freed from the binder by thermal processes and sintered to form a dense component.

Fused Deposition Modeling (FDM) or Fused Filament Fabrication (FFF)

- As with plastic 3D-printing for home use, a filament is melted and deposited layer by layer. However, the filament contains metal powder particles, which are then bonded by debinding and sintering to form a dense metal component.

How Much Does It Cost To 3D Print Metal Parts?

The cost of 3D metal printing can vary depending on several factors such as the size of the part, the complexity of the design, the type of metal used, and the number of parts being printed.

In general, the cost of 3D metal printing can range from a few hundred dollars for a small, simple part made of a less expensive metal, to tens of thousands of dollars for larger, more complex parts made of expensive metals such as titanium or cobalt chrome.

Additionally, the cost of the 3D metal printing equipment and maintenance, the cost of the metal powder or wire used, the cost of post-processing and finishing, and the cost of any necessary support structures or sacrificial elements also play a role in the overall cost.

It's worth to mention that the cost of 3D metal printing is generally higher than traditional manufacturing methods such as CNC machining or injection molding, but it also offers benefits such as reduced lead time, improved design flexibility, and the ability to create complex geometries that would be difficult or impossible to produce using other methods.

When does metal 3D-printing make sense for für for my part and application?

A component does not become better or more innovative as soon as it has been produced additively, and metal 3D-printing is also not a lifesaver for a failed component design.

Therefore, it is important to plan already in the design and development process purposefully with regard to the additive process chain and the resulting added values for the later application. We are happy to provide support with our engineering services and, together with our customers, can look back on many innovative reference projects as inspiration.

When is metal 3D-printing worthwhile?

When it comes to a direct comparison of the production costs of components from metal 3D-printing versus conventional manufacturing processes, we can often help very quickly with a holistic cost analysis to determine whether additive manufacturing is also technically and financially worthwhile for your application.

For prototypes and small series, metal 3D-printing can achieve significant advantages with fast delivery times and tool-free manufacturing - especially when time is prioritized over costs. All necessary processes before and after metal 3D-printing are available from a single source at Rosswag Engineering for maximum efficiency.

For series components, the advantage of the metal 3D-printing process is often the function-optimized geometry of the component. If, for example, subsequent process steps in machining or assembly can be saved as a result, there is a cost advantage. In addition, metal 3D-printing can also be used to introduce added value into the component that cannot be realized using conventional manufacturing processes. This results in significant cost savings, especially in subsequent operation, despite possibly higher manufacturing costs. Examples of this can be found in our reference projects.

How much do metallic components from 3D-printing cost?

The costs in the metal 3D-printing process are largely dependent on the component volume to be produced. Depending on the material and process parameters used, the costs in our LPBF process are thus between 3 - 15 €/cm³. We will be happy to provide you with a detailed offer and advise you on your requirements.