We are your Metal 3D-Printing service provider with a worldwide unique material diversity

Rosswag Engineering specializes in Additive Manufacturing by Selective Laser Melting (SLM® / LPBF) in a holistic and in-house process chain. This enables the efficient and economical production of functionally optimized metal components from many different alloys. The service portfolio ranges from tool production and prototypes with small quantities, to series production of functional components and specific consulting for the qualification of materials and parameters in an individual process chain.

Metal 3D-Printing Our Materials

Process Chain

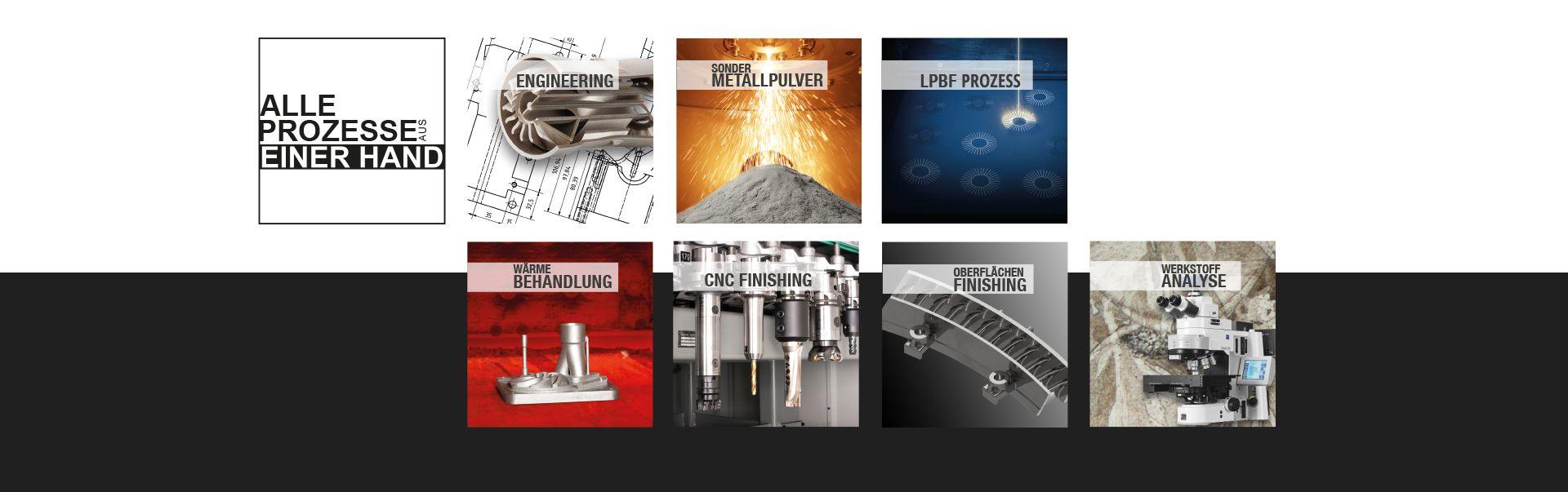

Rosswag Engineering offers a globally unique process chain for Metal Additive Manufacturing. The service portfolio ranges from tooling and prototype production with small quantities to series production with specific consulting services for the qualification of materials, process parameters and individual process chains for high-demanding parts.

Technical Engineering Day at KIT

More

Special Material Alert at Rosswag

More

MetalAM Enhances Injection Moulding Efficiency

More All

Additively manufactured series components

The additive manufacturing of metal components in our integrated process chain in accordance with the highest quality standards has been certified by TÜV SÜD in accordance with DIN SPEC 17071. Contact us if you require AM services in reproducible high quality, even for large quantities.

3D-printing metal powder

We were the first service provider worldwide to be certified by TÜV SÜD for our QM system and the associated process chain for the production of metal powders for Additive Manufacturing. Purchase individual metal powders for your Additive Manufacturing processes in highest quality directly from us!

Material qualification

as a service

We qualify well-known and new materials for metal 3D-printing until they are ready for series production! Rosswag's in-house process chain enables the world's fastest material qualification for the LPBF process. Our services range from atomization of individual alloys to metal powders, over simulation-based parameter studies up to the comprehensive analysis of test specimens. All work packages can be realized in very short cycle times. Only with us you will receive initial material qualification results within just a few days.

Reference projects

With our many years of experience as an innovative service provider for metal 3D-printing, we can look back on many exciting projects.

Whether additively manufactured machining tools or guide vanes for gas turbines. Learn more about the possibilities of industrial metal 3D-printing.