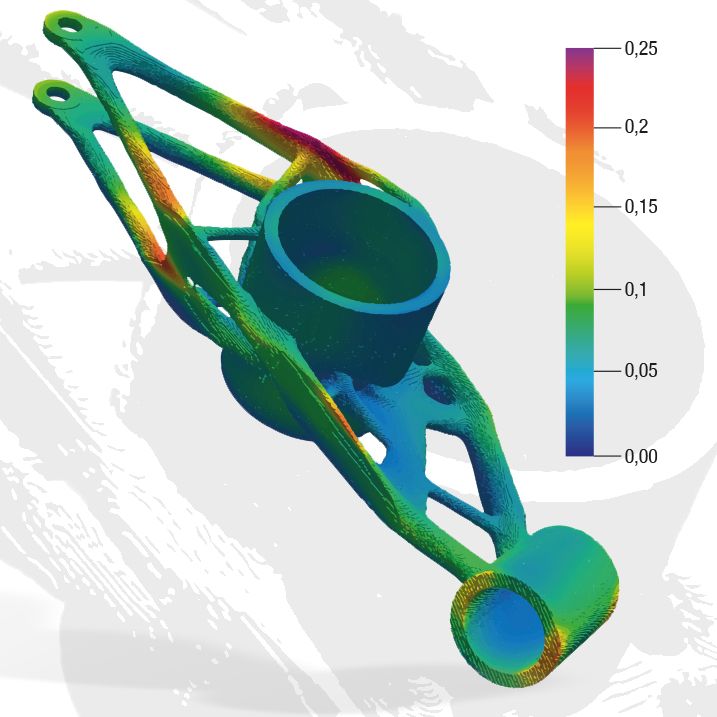

Metal 3D-Printing Process simulation

With the ANSYS Additive Suite simulation environment, we can already simulate and optimize the additive manufacturing process based on the initial CAD data. First, the resulting residual stresses and dimensional deviations are determined on the basis of the material and temperature data in the LPBF process. On this basis, adjustments to the process parameters and component geometries are possible in order to meet all requirements in a time-saving and cost-efficient manner even with the first functional samples. Calibration ensures high informative value for special materials and applications.