When I grow up powder Metal AM part Specialis

When I grow up, I will be a …❓

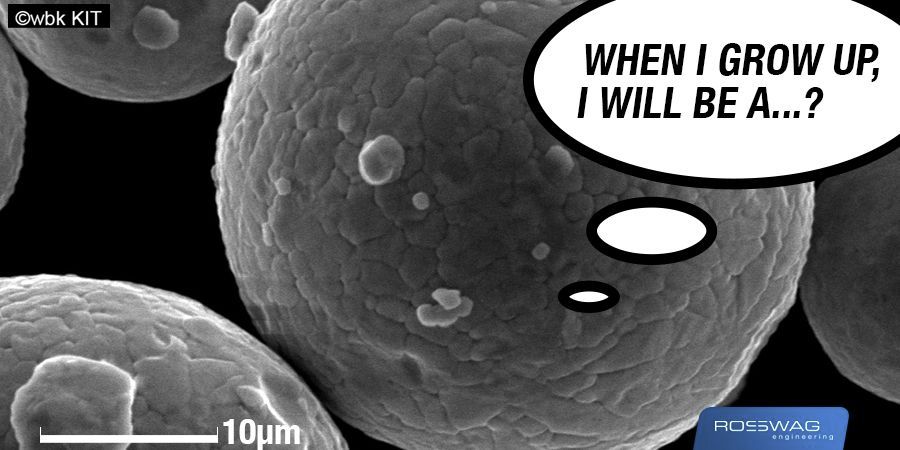

Small particles with big dreams on #MaterialsMonday

A small Specialis® particle produced by our atomizer can be transformed into many shapes by our LPBF Systems. But whether it ends up being a tool for stamping, injection molding or cutting, you can rely on the excellent mechanical properties:

✅ High hardness up to 810 HV (65 HRC) after heat treatment

✅ Low thermal expansion coefficient

✅ Good polishability

✅ High wear and corrosion resistance

✅ Superior high temperature strength and high temperature hardness

✅ Usable up to 550 °C and 19 kN pressing force without plastic deformation

Further information:

Other exclusive MetalAM materials by Rosswag Engineering: www.linkedin.com

Specialis® material datasheet: www.rosswag-engineering.de

Open Access Article - Unlock full potential of MetalAM for voxel-graded materials with synchronized dual-laser LPBF processing: www.linkedin.com