Case Study with Zeiss and Materialise

A Day’s Worth of Work in 20 Minutes: Automating MetalAM Process Parameter Development

Learn more about the great collaboration between Materialise, Zeiss IMT and Rosswag Engineering to bring MetalAM process optimization and material qualifications to the next level of industrialization.

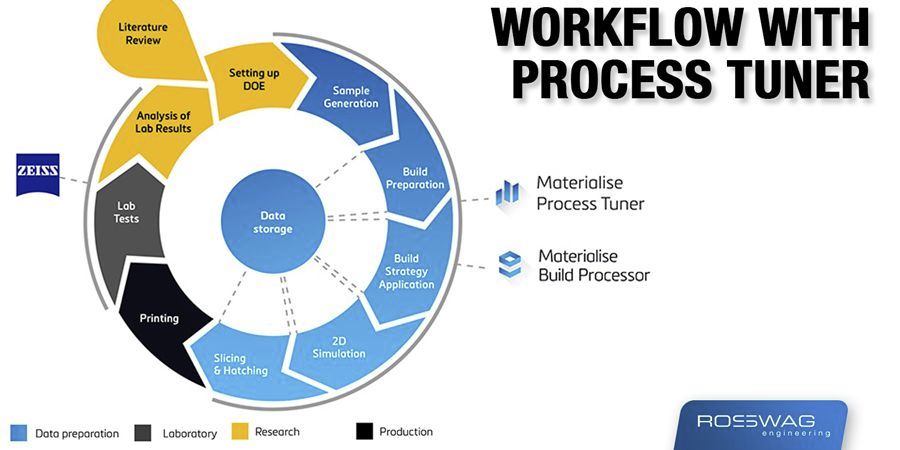

The new Process Tuner of Materialise streamlines collaborative process parameter development with automated workflows, insights, and an embedded database. At Rosswag Engineering we are already using the tool for a bunch of projects to bring new MetalAM materials to the market.

✅ Process optimization for critial and demanding applications

✅ Increase processing productivity with consistent material quality

✅ Fast qualification of new alloys for MetalAM

We will keep you updated with more information about the case study. Especially how we profit from the QA possibilities of Zeiss IMT!

🔗 Link to the case study:

A Day’s Worth of Work in 20 Minutes: Automating MetalAM Process Parameter Development

Learn more about the great collaboration between Materialise, Zeiss IMT and Rosswag Engineering to bring MetalAM process optimization and material qualifications to the next level of industrialization.

The new Process Tuner of Materialise streamlines collaborative process parameter development with automated workflows, insights, and an embedded database. At Rosswag Engineering we are already using the tool for a bunch of projects to bring new MetalAM materials to the market.

✅ Process optimization for critial and demanding applications

✅ Increase processing productivity with consistent material quality

✅ Fast qualification of new alloys for #MetalAM

We will keep you updated with more information about the case study. Especially how we profit from the QA possibilities of Zeiss IMT!

🔗 Link to the case study: www.materialise.com

Further information:

- Visit us at Formnext: www.linkedin.com

- Exclusive MetalAM materials by Rosswag Engineering: www.linkedin.com

- New milestone achieved with 60,000 MetalAM parts produced since 2014 with 40 different materials: www.linkedin.com