Strenghtening mechanisms of Specialisr

💡 Deep dive into the strengthening mechanisms of world's hardest LPBF maraging tool steel Specialis® on #MaterialsMonday

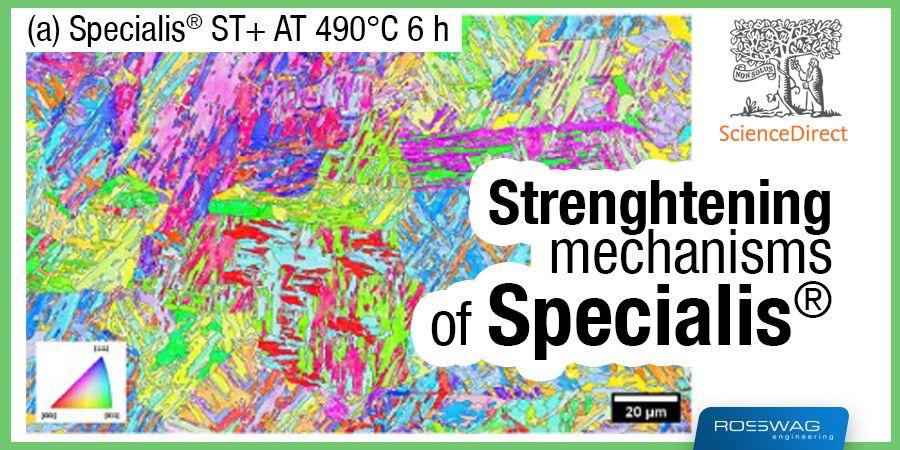

Kudos to our partners at IAM-WK: Institute for Applied Materials, KIT and especially Niki Nouri for publishing the great research paper with the title "Characterization of phase transformation and strengthening mechanisms in a novel maraging steel produced using laser-based powder bed fusion"

Highlights of the paper:

👉 Addition of V and Al leads to grain refinement in maraging steels.

👉 Intermetallic phases Ni3Ti and Fe2Mo are identified as hardening precipitates.

👉 The contributions of Hall-Petch and Orowan strengthening are separately calculated.

👉 The calculations show good agreement with the measured tensile strength difference.

🔗 Use this code to get 50 days of free access to the paper : authors.elsevier.com

Highlights of our exclusive Specialis® tool steel:

✅ Hardness up to 65 HRC / 820 HV after heat treatment

✅ High wear and corrosion resistance

✅ Superior high temperature strength and high temperature hardness compared to M300 and H13

✅ Good polishability

🤙 Get in touch with us to talk about your tool steel applications or demonstrator parts!

👉 Learn more about our 50+ qualified #MetalAM materials: www.rosswag-engineering.com