Ready for pressure equipment

How to produce parts by MetalAM according to the pressure equipment directive ❓ You definitely need a lot of samples and some statistics before 📊 MaterialsMonday

When being certified by TÜV Süd for the production of high-quality metal powder and serial parts isn't enough for providing the best MetalAM solutions for our clients, we need to move on along our vision…

➡️ Next step: Certification of our manufacturing processes and QM system to produce MetalAM parts according to the 🇪🇺 pressure equipment directive 2014/68/EU

Insights into our qualification data set of the samples produced on our SLM Solutions 280 Twin system with 316L:

🔵 1 Qualified metal powder batch

🔵 5 Build jobs

🔵 1 Solution annealing heat treatment process

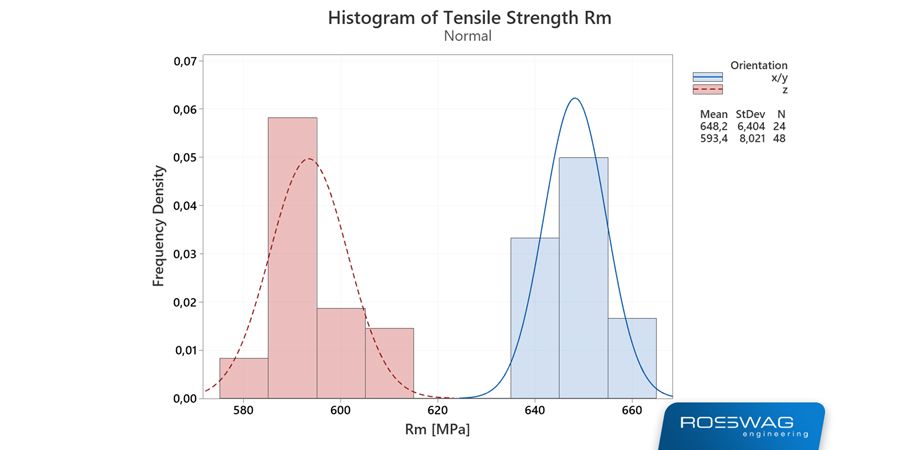

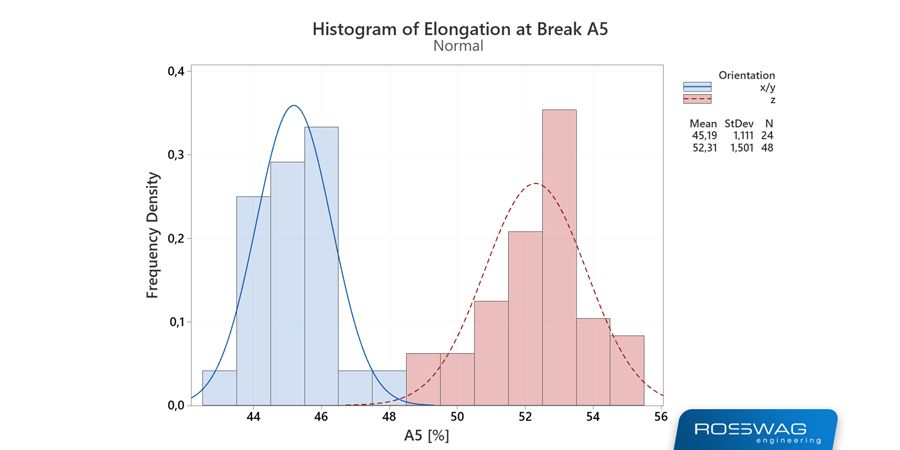

🔵 72 Tensile strength tests (24 produced in x/y and 48 produced in z)

🔵 72 Charpy notch tests in different build directions and positions of the notch axis

Initial results:

☑️ Tensile strength ↔️ 648.17 ± 6.40 MPa (SD) ↕️ 593.40 ± 8.02 MPa (SD)

☑️ Elongation at break ↔️ 45.19 ± 1.11 % (SD) ↕️ 52.31 ± 1.50 % (SD)

☑️ Verifiable Rm deviation for the positioning within a build job (x,y and z): 6 MPa

☑️ Verifiable Rm deviation between the build jobs with significant changes in layer exposure times: 20 MPa

You need more information regarding this topic ❓

The Additive Manufacturing Conference of Pressure Equipment, hostet by TÜV Süd, was postponed to 2022 and will be held in Munich.

The conference is specially designed for manufacturers and operators of pressure equipment with topclass presentations and different workshop formats. Rosswag Engineering will participate at the event with no less than 3 presentations:

👨🏫 "Quality assurance during production – qualification / certification" by Jonas Koch and Martin Boche

👨🏫 "Metal powders for additive manufacturing – production, characteristics and impact" by Daniel Beckers

👨🏫 "High-Performance 3D Heat-Exchanger for high-temperature Applications" by Philipp Schwarz

Further information:

- Conference registration and further information: www.tuvsud.com

- Information about the TÜV Süd AM services: www.tuvsud.com

- High performance MetalAM heat exchangers by Rosswag and Hülsenbusch: www.linkedin.com