Powder Moisture

💧 Powder moisture ❌ An often underestimated problem in the #MetalAM process chain #MaterialsMonday

Correct powder handling is crucial for the subsequent component quality in the LPBF process. If metal powder comes into contact with the ambient air, it very quickly absorbs moisture from the air and the powder's flowability and other properties deteriorate.

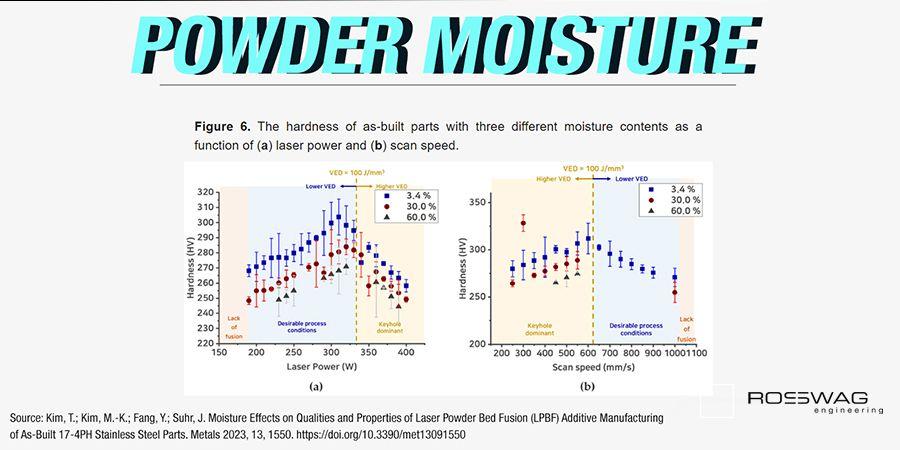

We have found a very interesting paper about "Moisture Effects on Qualities and Properties of Laser Powder Bed Fusion (LPBF) Additive Manufacturing of As-Built 17-4PH Stainless Steel Parts by the Department of Mechanical Engineering, Sungkyunkwan University. Hardness and density deteriorate significantly when using moist powder!

Rosswag has several measures in place to dry our powder and ensure continuous quality assurance:

✅ Measurement of moisture content and flowability of all new powder batches

✅ Vacuum drying module from AMProved for fast drying of metal powders

✅ In-house developed moisture monitoring in the main tank of our SLM Solutions systems

✅ In-house developed recoater unit to simulate the flowability and behavior during coating

🔗 Learn more about the moisture effects on laser powder bed fusion parts here: www.mdpi.com