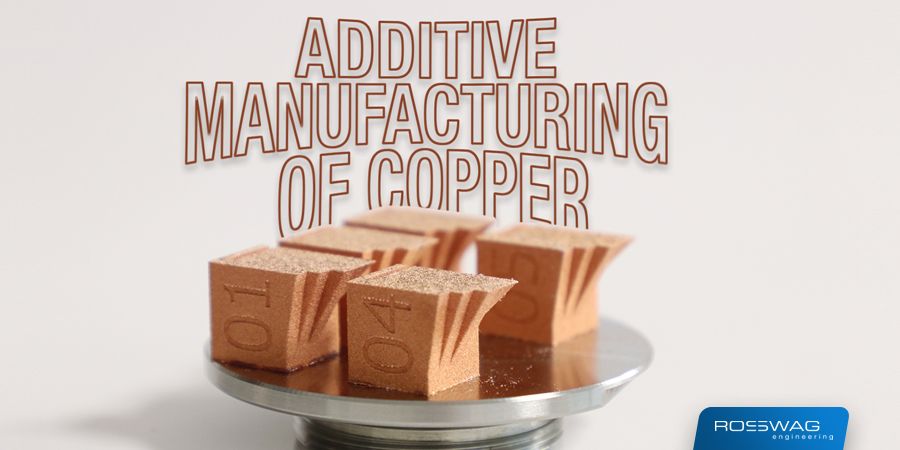

Additive Manufacturing of Copper

Copper is used by humans from circa 8000 BC - and is finally also processed by additivemanufacturing at Rosswag Engineering MaterialsMonday

We did our preliminary parameter studies with pure copper on our small Alpha Laser system. 200 W on a 50 µm laser spot is well suited to couple in the needed laser energy even though the bad absorption coefficient.

This is just the starting point for some industrial and R&D projects on our roadmap to look deeper into the possiblities of copper processing with our red laser LPBF systems:

🔵 Qualification of coated copper powders for better absorption with red laser LPBF processing

🔵 Qualification of new copper alloys we are atomizing currently for high-performance gliding applications

Stay tuned and contact us for your special need in LPBF copper processing 🤙

Further information:

- Your material is not yet qualified for Metal AM? Get a free qualification worth €50,000+ on AddiMap: www.addimap.com

- Subscribe our Newsletter

- You want to have a look at our extensive MetalAM material portfolio? Check our subsite: www.rosswag-engineering.de

- Case Study: Rapid qualification of new MetalAM materials and parameters with Zeiss Industrial Metrology, Materialise and Senvol: www.linkedin.com