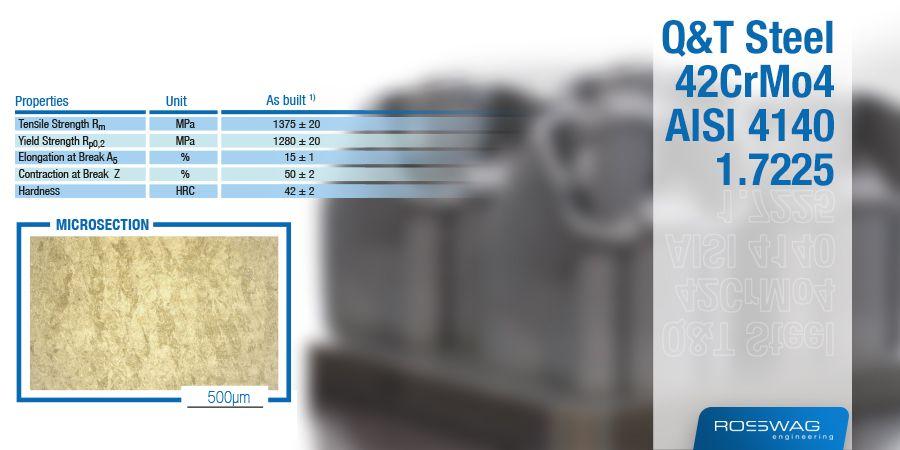

42CrMo4 Q&T: Automotive Steel 42CrMo4/AISI 4140/1.7225

Q&T steel AISI 4140 / 1.7225 / 42CrMo4 with superior mechanical properties ready to #3DPrint 🚗⚙️💪 Plug&Print with AddiMap #MaterialsMonday

The potential of #MetalAM for high-end automotive and industrial applications is enormous! And at Rosswag Engineering we have a well-known and fitting material qualified for protoyping and serial applications.

With the Q&T steel qualification of AISI 4140 / 1.7225 / 42CrMo4 we achieved superior mechanical properties with optimized process parameters and alloy chemistry. We tested countless material properties and can also deliver fatigue results with our unique flat-bending test according to DIN 50142.

You can find the full datasheet on our website: www.rosswag-engineering.com

Plug&Print: If you have a SLM280 from SLM Solutions, you can buy the fitting and validated alloy chemistry and process parameters on AddiMap 😮

FAQS: 42CRMO4

Here you can find more helpful information regarding 42CrMo4.

What is 42CrMo4?

42CrMo4 is a versatile medium-carbon low alloy steel with high strength and good hardenability. Its resistance properties can be increased through quenching and tempering. 42CrMo4 steel is suitable for manufacturing plastic molds.

What is Q&T steel?

Q&T stands for quenched and tempered. It describes a two-step heat treatment to improve the properties of steel. First, the steel is brought to an extremely high temperature and then immediately cooled down with water or oil. This step is called being quenched. After cooling down the steel is hardened yet brittle. Therefore, it is reheated and afterwards cooled at normal air temperature (tempered) to increase toughness and ductility. The overall process of Q&T is supposed to modify the microstructure of the steel to achieve the desirable strength for a range of engineering applications.

What temperature is quenched and tempered?

During the Q&T process the steel (such as 42CrMo4) is first heated at a temperature of 850°- 880°C (1560°-1620°F) and then quenched at 150° to 700°C (300°F to 1,300°F), depending on the purpose. The temperature also varies depending on the steel.

What is 42CrMo4 used for?

Possible applications for 42CrMo4 include heavy machinery parts, crankshafts, conveyors and rolls, gears, drill collars and steel couplings.

Does 42CrMo4 rust?

Environmental factors play a role in the development of rust. In Order to prevent rust or corrosion, a surface anti-corrosion treatment with oil can for example prevent or minimize rust. Nevertheless, 42CrMo4 steel has the potential to corrode over time.

Where can find more helpful information regarding metal 3d-printing?

More helpful information regarding metal 3d-printing can be found in our FAQ section.